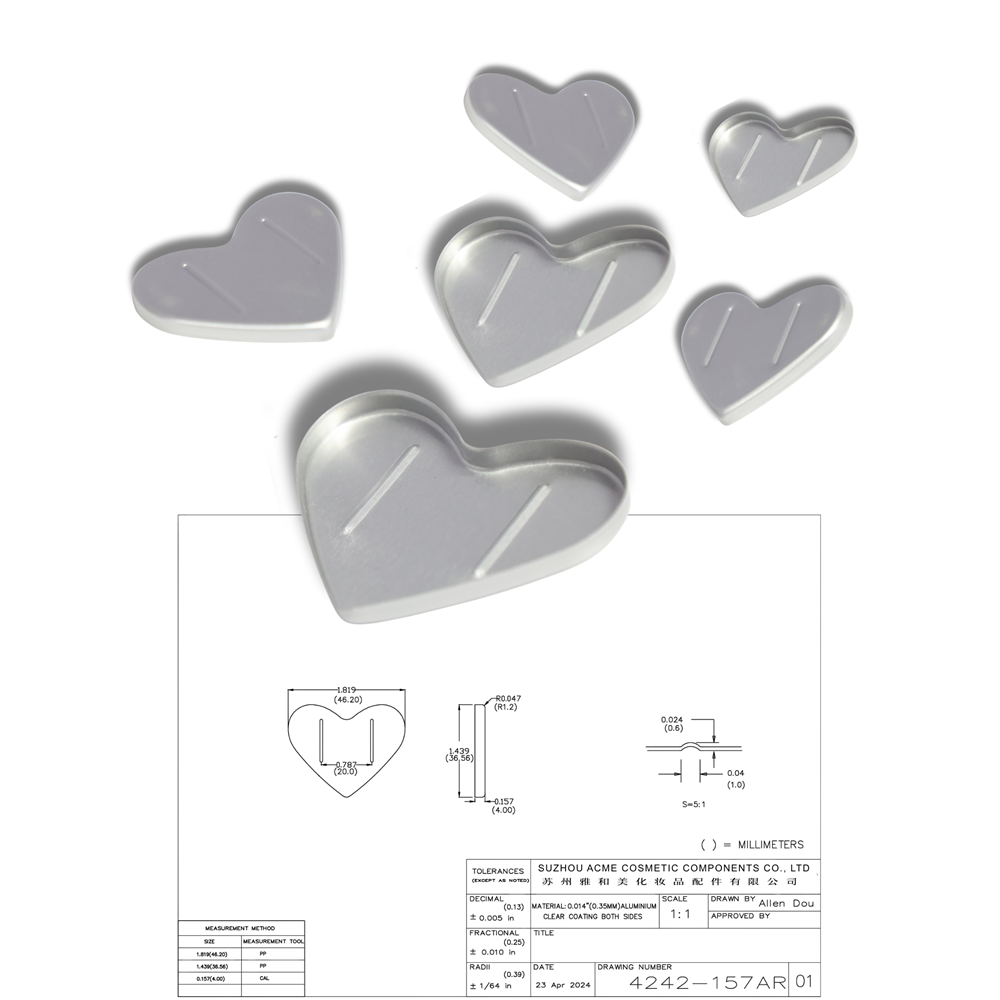

When custom tooling is required, our engineers will design a pan, based on its new dimensions, tolerances, material and special features. They also pay particular attention to allow for “drop-in” performance, enabling the filled component to enter a compact without binding.

In order to better support the development of some special-shaped products, with the support of time and budget, we will use 3D printing technology to simulate the products and pre-assemble them to ensure the perfect performance of the customer's finished products.

In addition, we place great emphasis on providing reasonable design and material combinations to ensure a smooth manufacturing process, minimize waste, and achieve more cost-effective results. Once the new molds are completed, we will produce samples for the engineering and quality assurance departments to verify the dimensions and surface quality.